GIDINGS&LEWIS 810-21276-02系統(tǒng)電路板

1.產(chǎn) 品 資 料 介 紹:

GIDINGS&LEWIS 810-21276-02 系統(tǒng)電路板

產(chǎn)品概述

產(chǎn)品應(yīng)用領(lǐng)域

數(shù)控機(jī)床系統(tǒng)

自動(dòng)化生產(chǎn)線

工業(yè)機(jī)器人控制系統(tǒng)

包裝與印刷設(shè)備

測(cè)試與精密加工系統(tǒng)

英文資料:

GIDINGS&LEWIS 810-21276-02 System Circuit Board

Product Overview

The 810-21276-02 system circuit board is the core auxiliary module of the Giddings&Lewis control system, with three main responsibilities: firstly, precise management of internal signal allocation to ensure that various control signals are transmitted without conflict or delay; The second is to coordinate the operation of communication interfaces and adapt to the connection requirements of different modules; The third is to coordinate the data exchange between key devices such as CPU modules, input/output modules, and servo drives. It is like a "signal hub" of the system, ensuring stable and efficient operation of the entire control system through bridging and collaborative effects.

Product application areas

Numerical Control Machine Tool System

In CNC machine tools, this circuit board is responsible for distributing and coordinating internal system signals, with a focus on ensuring spindle speed control and stable transmission of motion commands for each feed axis, to avoid affecting machining accuracy due to signal fluctuations. At the same time, it supports multi module linkage of machine tools (such as tool magazine module, cooling module), providing a reliable signal foundation for high-precision milling, turning and other machining tasks of complex parts.

Automatic production line

For automated production lines, circuit boards mainly manage data communication between various control modules (such as robotic arm controllers and conveyor system drivers), ensuring the coordination of robotic arm grasping, conveyor equipment start stop, and actuator actions, and avoiding process disconnection. In addition, it also undertakes the function of system power distribution and provides standardized signal interfaces to ensure the continuous and stable operation of various modules in the production line.

Industrial Robot Control System

In industrial robot systems, circuit boards serve as signal transmission bridges for robot controllers, joint servo drivers, and position feedback sensors, enabling precise bidirectional transmission of control instructions and feedback data. This feature supports robots to complete complex path planning (such as circular arc trajectories, multi segment line movements) and multi axis collaborative operations (such as arm end effector linkage), ensuring action accuracy and operational stability.

Packaging and Printing Equipment

For packaging machines, printing machines, and other equipment, the core role of circuit boards is to coordinate the signal transmission of various motion axes (such as feeding axes, printing drum axes) and synchronous equipment, ensuring that the equipment maintains synchronized motion during continuous operation and avoiding problems such as material deviation and inaccurate printing. At the same time, it provides signal interfaces that can provide real-time feedback on equipment operating speed, processing position, and action status, making it easy for operators to monitor and fine tune.

Testing and Precision Machining System

In experimental testing platforms or precision processing equipment (such as semiconductor wafer processing equipment), circuit boards provide a stable data communication foundation for multi-channel control, supporting precise control of multiple testing points or processing stations simultaneously. In addition, it can adapt to high-speed data acquisition requirements, and with real-time signal processing functions, meet the strict requirements of precision testing and micrometer level processing for data timeliness and accuracy.

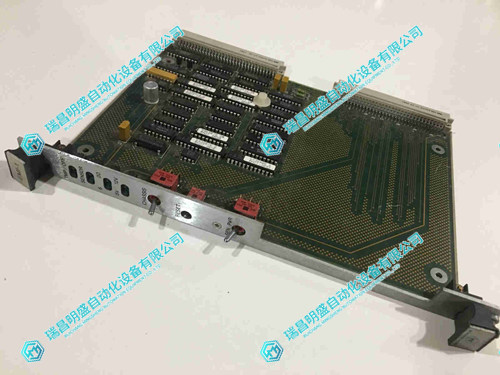

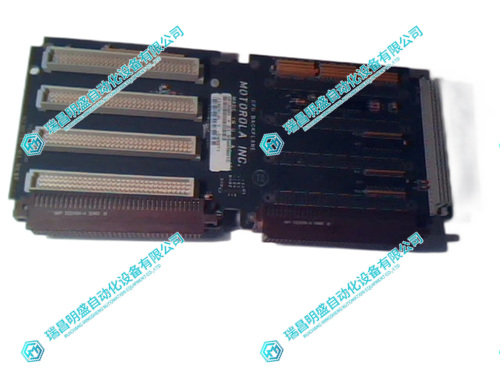

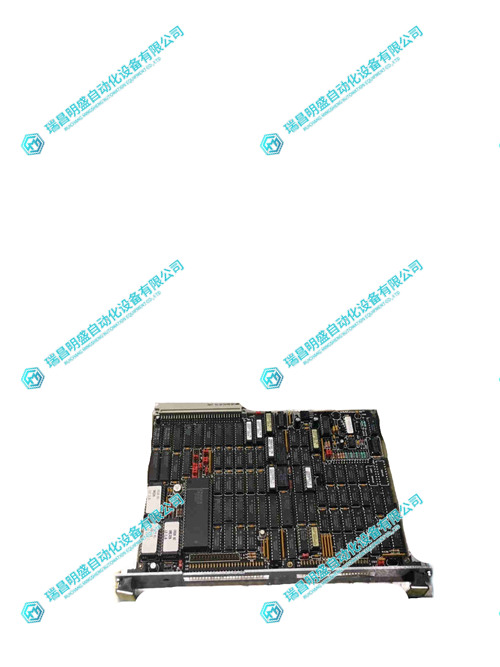

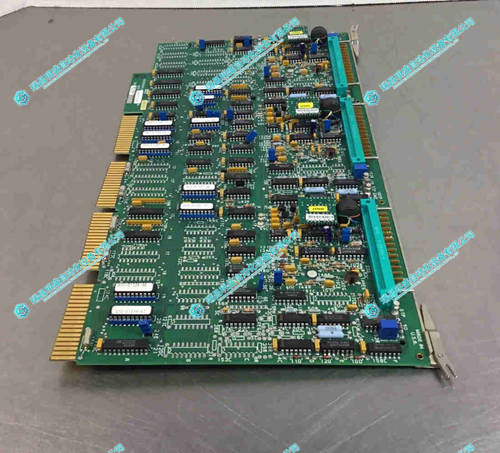

2.產(chǎn) 品 展 示

3.其他產(chǎn)品

GALIL DMC-1832總線運(yùn)動(dòng)控制卡

ETHERWAN EMC1600以太網(wǎng)交換機(jī)

4.其他英文產(chǎn)品

Radisys ATCA-PP81 controller module

AMAT 0190-24282 encoder module

IC3600EPSS1B power supply boar

| AMAT 0190-81774 | AMAT 0190-35845 | AMAT 0190-13021 |

| AMAT 0190-64232 | AMAT 0190-35857 | AMAT 0190-13025 |

| AMAT 0190-62317 | AMAT 0190-35861 | AMAT 0190-13035 |

| AMAT 0190-35683 | AMAT 0190-35928 | AMAT 0190-13038 |

| AMAT 0190-76053 | AMAT 0190-35961 | AMAT 0190-13038 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218