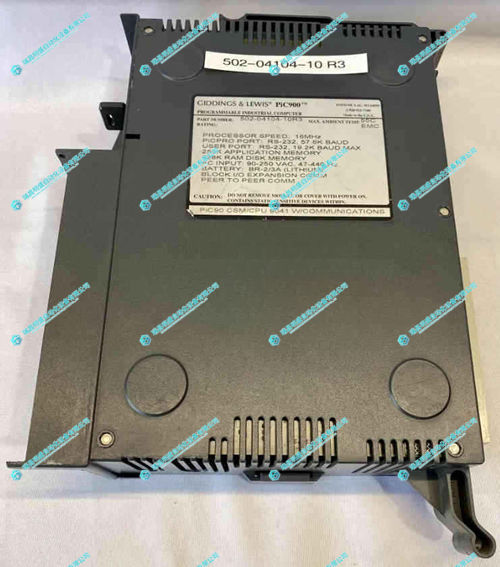

GIDDINGS & LEWIS 502-04104-10通信模塊

1.產(chǎn) 品 資 料 介 紹:

產(chǎn)品概況

技術(shù)參數(shù)

應(yīng)用場(chǎng)景

數(shù)控機(jī)床系統(tǒng)

工業(yè)自動(dòng)化生產(chǎn)線

設(shè)備遠(yuǎn)程監(jiān)控與數(shù)據(jù)采集

多設(shè)備集成與網(wǎng)絡(luò)擴(kuò)展

英文資料:

Product Overview

The GIDINGS&LEWIS 502-04104-10 communication module is an industrial grade data interface device developed specifically for CNC machine tools and automation control systems. The main function of this module is to achieve data exchange between the controller, CPU module, I/O module, and upper computer, ensuring efficient communication and collaborative operation among various units in the system. It adopts an industrial standard bus interface, which can adapt to complex industrial environments and ensure stable and reliable data transmission.

Technical Specifications

Product Type: Industrial Communication Module

Model: 502-04104-10

Core function: Responsible for data transmission, protocol conversion, and serving as a system communication interface

Interface type: Equipped with standard industrial bus interface (can support multiple bus protocols)

Data rate: Capable of high-speed data transmission, meeting the needs of real-time control

Compatibility: Seamless compatibility with logic controllers, CPU modules, and I/O modules

Power specification: Adopting DC 24V industrial power supply

Environmental adaptability: able to withstand high temperature, high humidity, and industrial vibration environments

Protection function: adopting short-circuit and overvoltage protection design, with anti electromagnetic interference capability

Application scenarios

Numerical Control Machine Tool System

Implement data communication between CPU modules, logic controllers, and multi axis servo systems.

Ensure the real-time coordination of machine tool actions and multi axis synchronous control.

Industrial automation production line

Support high-speed information exchange between various modules of the production line to achieve action scheduling and process optimization.

It can connect sensors, actuators, and upper monitoring systems to help achieve intelligent production.

Remote monitoring and data collection of equipment

Realize data exchange between the controller and the upper computer or MES system, facilitating production monitoring and management.

Support real-time status collection, alarm notification, and data recording functions.

Multi device integration and network expansion

Can be used to expand industrial communication networks and achieve collaborative work among multiple control units.

Provide stable data channels to ensure the overall performance of large-scale automation systems.

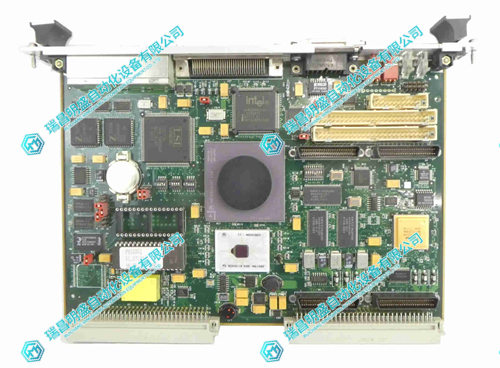

2.產(chǎn) 品 展 示

3.其他產(chǎn)品

INDRAMAT TDM1.3-050-300-W1-000 驅(qū)動(dòng)模塊

4.其他英文產(chǎn)品

Bentley 330980-50-05 proximity sensor

SANYO P30B0601DXS8SM servo motor

| T22NRHJ-LDN-NS-00 | GESPAC GESDAC-2B 8945 | 061-04790-0012 |

| T21NRLH-LNN-NS-00 | 6SC6120-0FE01 | 125760-01 |

| T21NRLD-LNN-NS-00 | 6SC6170-0FC01 | 6ES5451-4UA12 |

| T21NRLC-LNN-NS-00 | GESPAC GESDMC-2 | 6ES5135-3UA11 |

| T21NRHJ-LNN-NS-00 | 6SC6100-0GA12 | 3500/32M 149986-02 |

| T21NLLC-LNN-NS-00 | CACR-SR15BB1CS | 6ES5441-8MA11 |

Contact: +86 15270269218